Graphic Overlay and Panels-- Precision Engineering for Control Panels and Displays

Graphic Overlay and Panels-- Precision Engineering for Control Panels and Displays

Blog Article

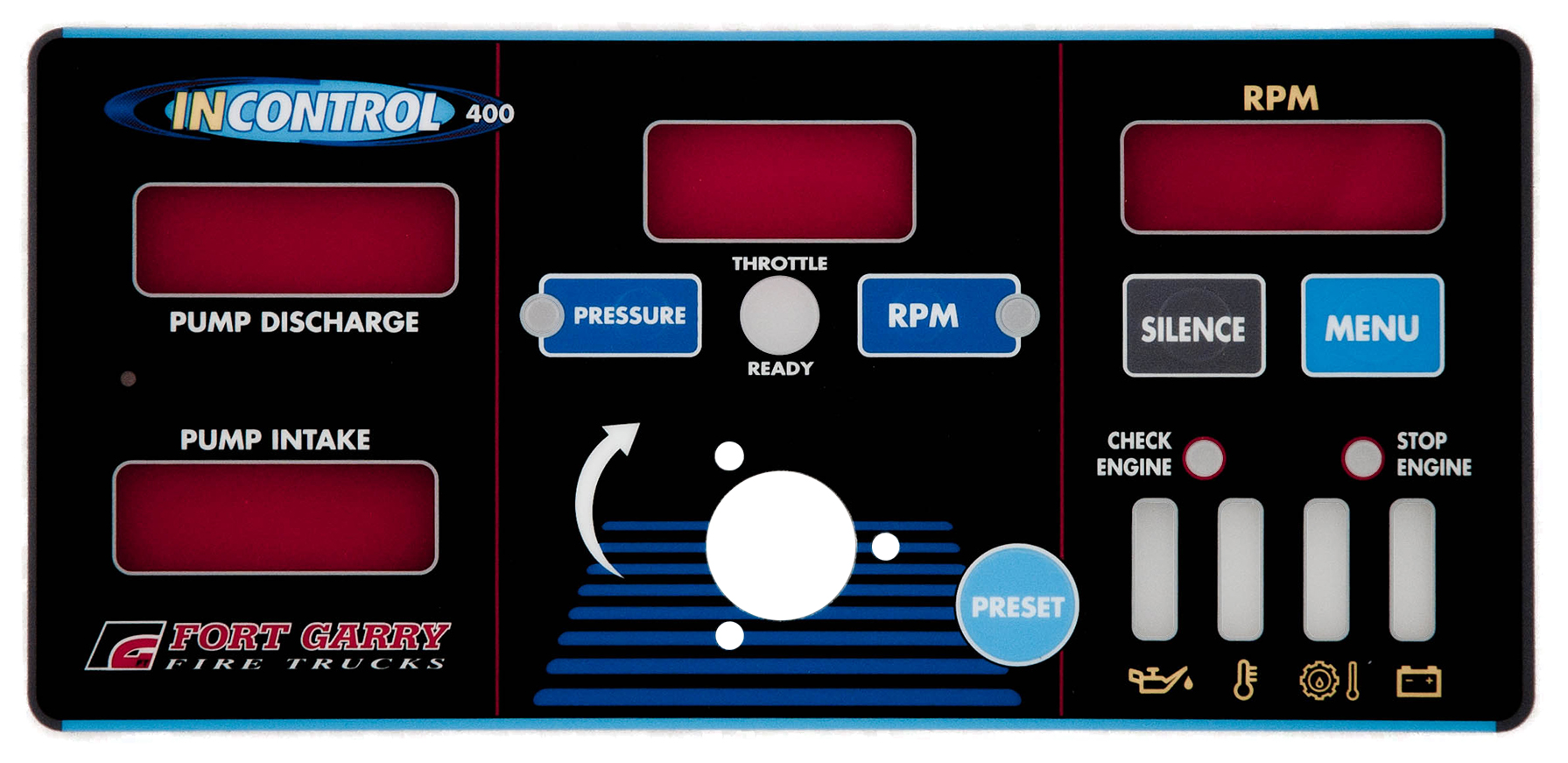

Trick Elements to Consider When Creating Graphic Overlays and Panels

In the realm of graphic overlays and panels, a number of crucial factors warrant careful consideration to guarantee optimum functionality and longevity. Additionally, one must account for ecological conditions that can affect the overlay's honesty and compliance with regulative standards.

Material Choice

When it concerns graphic overlays and panels, material selection plays a crucial duty in figuring out both capability and looks. The choice of products dramatically affects the durability, look, and efficiency of the overlays, ultimately affecting individual experience and product longevity.

Common products consist of polycarbonate, polyester, and vinyl, each offering distinct advantages. Polycarbonate, as an example, is understood for its high effect resistance and quality, making it appropriate for high-traffic settings where toughness is essential - Graphic Overlay and Panels. Polyester, on the other hand, uses outstanding chemical resistance and is ideal for applications exposed to harsher conditions. Vinyl, while much less resilient, can be an affordable selection for temporary applications where versatility and convenience of printing are required.

Furthermore, the thickness and appearance of the material can boost responsive responses and aesthetic appeal, additional contributing to customer communication. Factors such as UV security, temperature resistance, and adhesive compatibility are also important considerations throughout material selection. Inevitably, the best material not only lines up with the layout goals yet also guarantees that the graphic overlays and panels effectively offer their desired function, keeping both capability and aesthetic integrity over time.

Interface Design

Effective user interface layout is important for boosting user experience and guaranteeing user-friendly interaction with visuals overlays and panels. A well-designed user interface not only facilitates user engagement yet likewise lowers the learning curve related to brand-new technologies. This is specifically crucial in environments where quick decision-making is essential, such as medical devices or commercial control systems.

To attain efficient interface style, quality is paramount. Symbols, buttons, and various other aesthetic aspects ought to be conveniently recognizable and share their features without uncertainty. The usage of consistent color pattern, typography, and design creates a cohesive experience that overviews users via interactions smoothly.

Moreover, the positioning of controls should be intuitive, enabling users to browse the user interface normally. This entails thinking about the individual's operations and creating overlays that minimize unnecessary actions. Comments systems, such as visual or auditory signals, can likewise improve use by confirming individual activities and supplying support.

Durability and Longevity

Toughness and long life are crucial consider the style of visuals overlays and panels, particularly in demanding atmospheres where devices undergoes tear and put on. Developers need to prioritize materials and construction approaches that can withstand physical, mechanical, and chemical stress and anxieties over time.

The option of materials plays a substantial duty in making sure durability. Using polycarbonate or polyester films can boost resistance to scratches, influences, and fading. Furthermore, incorporating UV-resistant finishes can assist preserve appearance and functionality under long term direct exposure to sunlight.

Adhesive selection is equally essential, as it needs to supply strong bonding while permitting thermal expansion and tightening. A top notch adhesive will prevent delamination and make certain that the overlay stays securely attached under numerous problems.

Ecological Problems

Ecological problems play a significant duty in the efficiency and longevity of visuals overlays and panels. Aspects such as temperature level, moisture, UV direct exposure, check it out and chemical direct exposure needs to be diligently taken into consideration throughout the design procedure. High temperatures can bring about distortion or bending, while severe cold might result in brittleness, impacting the overlay's stability.

Humidity can cause adhesion problems, possibly causing delamination or bubbling, which endangers the functional and aesthetic facets of the panel. UV direct exposure is one more essential factor to consider; long term sunlight can create fading and degradation of the graphics, necessitating making use of UV-resistant products or finishes to preserve aesthetic appeal and readability in time.

Additionally, atmospheres that reveal overlays to severe chemicals, such as cleansing representatives or industrial substances, can lead to product deterioration. Selecting substratums and inks that are immune to such chemicals is vital to ensure sturdiness.

Inevitably, comprehending the particular ecological conditions in which the graphic overlays and panels will operate allows developers to pick suitable products and style strategies, hence boosting both efficiency and long life. (Graphic Overlay and Panels)

Governing Compliance

Just how can suppliers guarantee that their graphic overlays and panels meet necessary governing standards? Conformity with industry policies is vital for producers to preserve security and capability in their products. To attain this, manufacturers ought to first determine the relevant requirements that put on their specific applications. As an example, overlays made use of in medical devices might require to follow FDA guidelines, while those for auto applications have to follow ISO requirements.

Additionally, performing regular testing of products and models versus established criteria is important. This aggressive strategy enables early detection of potential conformity problems. Lastly, staying informed concerning adjustments in standards and policies is vital, as this landscape can develop rapidly. By incorporating these techniques, makers can guarantee their graphic overlays and panels not only fulfill regulatory demands but likewise improve Extra resources item reliability and customer trust.

Conclusion

In final thought, the style of visuals overlays and panels necessitates careful factor to consider of a number of vital aspects. By resolving these elements, developers can develop efficient and long-lasting graphic overlays and panels that satisfy diverse needs.

In the world of graphic overlays and panels, numerous essential aspects require mindful consideration to make sure ideal performance and durability. Ultimately, the best product not just straightens with the layout objectives however likewise makes certain that the visuals overlays and panels successfully offer their intended purpose, keeping both functionality and visual honesty over time.

Effective user interface layout is vital for enhancing customer experience and guaranteeing user-friendly interaction with graphic overlays and panels. By integrating these techniques, suppliers can ensure their graphic overlays and panels not just satisfy regulatory needs yet also improve item dependability and customer trust Visit Website fund.

In final thought, the style of visuals overlays and panels necessitates cautious consideration of a number of critical elements.

Report this page